Instructions for pre-glued

Step 1, Preparation

Before installation, allow veneer to acclimate for 24 hours at the installation location, under normal conditions. The surface must be smooth, clean and free of grease or other contaminants. Cut the veneer oversize approximatly 1/4" larger than the area to be covered.

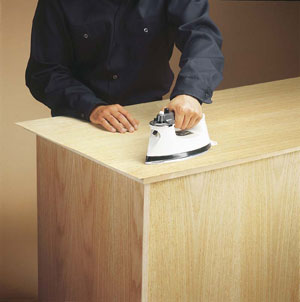

Step 2, Application

If the surface is not bare wood or the equivalent, adequate sanding will allow for better adhesion.Preheat a high-temperature iron (204 C - 400 F), and place a piece of packaging paper between the iron and the surface to protect the surface against scratches and burns. Slide the iron slowly from the centre of the sheet toward the sides, applying steady pressure. Regardless of the glue used, adequate pressure is necessary to achieve a good bond.

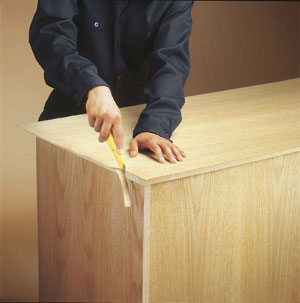

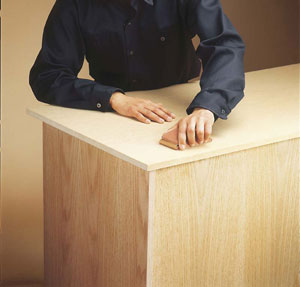

Step 3, Trimming

After allowing the veneer to dry for a few hours, check for air bubbles by shining a light across the wood grain. Eliminate air bubbles by making an incision in them, and then using a hot iron to reactivate the glue. Press down firmly to rebond. Using a sharp knife, carefully follow the edge of the sheet.

Step 4, Finishing

Since the surface of the veneer sheet is pre-sanded at the factory, only a light sanding with fine sandpaper is required for the edges. (Do not sand pre-finished veneers). The trimmed edges of the pre-varnished veneer must be touched up using a varnish pencil. Unvarnished veneers must be treated with a layer of sealant, a stain if required, and one or two coats of varnish, according to the manufacturer's instructions.

MORE TIPS AND GUIDES

Tenderized Wood Veneer SheetsWood Veneer Edgebanding

Thick Edgebanding

Pre-varnished Products

Wood Weave Panels

Peel and Stick

Paper Backed

PDF DOCUMENTS

Technical information on natural characteristics of woodPresentation and technical information on Greenguard certified products

Description of available backer types

Things you should know when purchasing veneer sheets

Relationship between temperature and humidity in wood

Presentation and technical information on engineered wood product EVOLUTION HD

Veneer matching and arrangement types

Technical information on veneer cutting methods